Aluminum and strength

August 24, 2015 at 1:57 PM by Dr. Drang

Last week, a new iPhone bending video was released by Unbox Therapy. It compares the shell of the current iPhone 6 to that of a new shell that’s said to be from the upcoming iPhone 6S. I didn’t comment on last year’s video because there just wasn’t enough meat in it to chew on. This new video, though, has enough engineering content to be worth discussing.

On the off chance you haven’t seen the new video, here it is:

There are basically two parts to it:

- Elemental analyses of the aluminum alloys used in the current and “new” shells.1

- Mechanical testing of the current and new shell.

I’m going to discuss these in reverse order, critiquing and adding missing detail. Although the video is nearly twelve minutes long, it’s light on detail, with much of the time being spent telling us how cool Lew is. This is unnecessary—we can tell how cool Lew is from his backwards baseball cap.

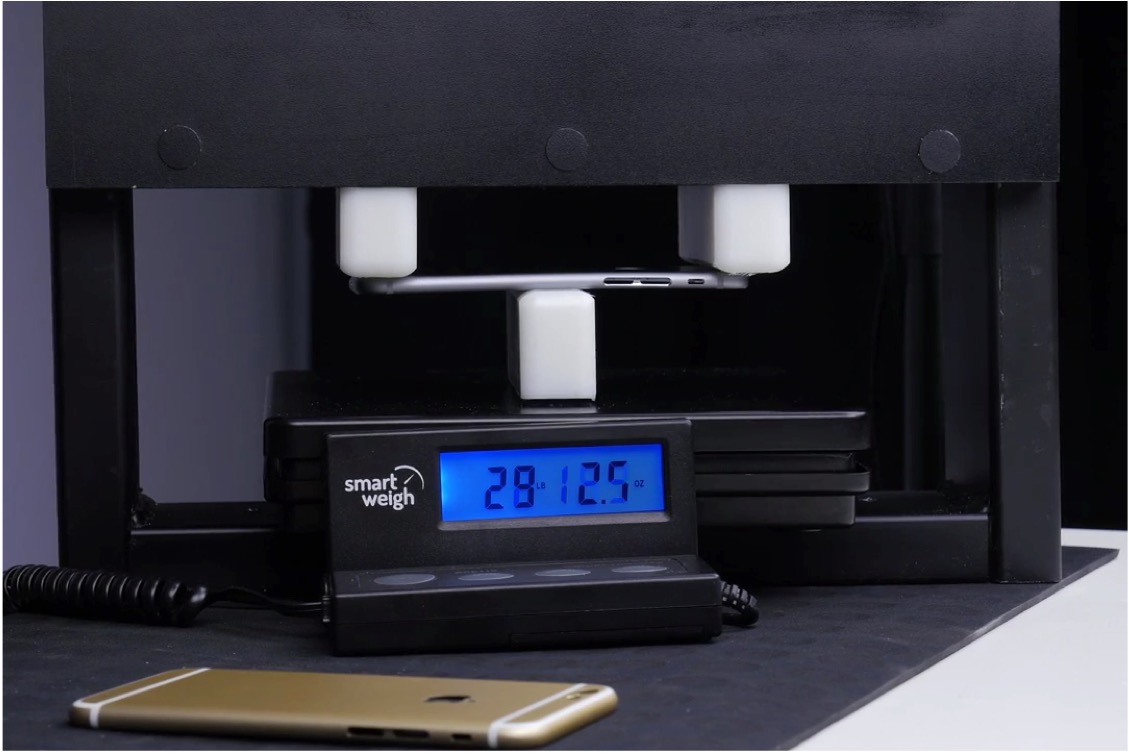

The mechanical test is a three-point bend test, so called for obvious reasons. The test frame is made from rectangular tubing welded together, and the crosshead, which looks like it’s made of wood, is driven by hand through a threaded rod. The loading is applied through three plastic (polyethylene?) blocks with chamfered edges and is measured by a scale that sits on the bottom member of the test frame.

Screen capture from Unbox Therapy.

The test of the current iPhone 6 shell starts at about 6:30 and the test of the new shell starts at about 8:30. The point of each test is to determine the load at which the shell takes on a permanent deformation. This permanent deformation comes through yielding of the shell’s aluminum, possibly accompanied by local buckling of the sidewall.

The tests are not well run. There are no marks made on the shells to ensure that they’re loaded at the same locations. The crosshead wanders from side to side, changing the points of load application while the tests are running. The scale wobbles on the lower member of the test frame during the second test. There is nothing measuring the vertical crosshead movement, so there’s no consistent way of determining when the shell yields. Some of these problems could be addressed by developing a better testing technique; some can only be addressed by building a better test frame.

Despite these deficiencies, Lew’s basic conclusion holds: the new shell is far stronger than the current one. I wouldn’t trust any of the numbers, but there’s no question that his qualitative result is correct.

Why is the new shell so much stronger? The possibilities are stronger material, better structural geometry, or a combination of both.

The video, unfortunately, tells us nothing about the geometry of the new shell. It’s clearly the same on the exterior, but we don’t know whether the sidewalls have been thickened or reinforced by machining stiffeners into the interior. Maybe this was covered in an earlier video, but I think it should have been discussed here because it affects the strength of the shell.

Update 8/24/15 7:38 PM

The new dimensions were covered in an earlier video and Lew’s measurements of the sidewalls showed them to be thicker in the areas around the button cutouts. Thanks to Abdel Ibrahim for sending me the link.

Which leaves us with the elemental analyses of the two shells. This part of the video is pretty well done, mainly because the work was done by a professional laboratory.

The technique they used was X-ray fluorescence (XRF), as packaged in a nice handheld unit. Like other spectral methods, it involves shooting a beam of particles or electromagnetic radiation at the part and keeping track of the subsequent electromagnetic emissions. Each element has its own characteristic set of emission frequencies, so the spectrum gathered by the detector can be analyzed to determine the elements in the alloy.

The software that performs the analysis does two things:

- It reads both the frequencies and intensities of the spectral lines to determine the weight percentages of the elements present.2

- It compares the composition to a database of alloys and chooses the best match.

The database match isn’t, and can’t be, perfect. Because alloys commonly specify ranges and upper limits for each element, there are overlaps. Just because the software says a material is Alloy A doesn’t mean it can’t also fit within the specification for Alloy B. This is where human interpretation and expertise in material specifications comes in handy.

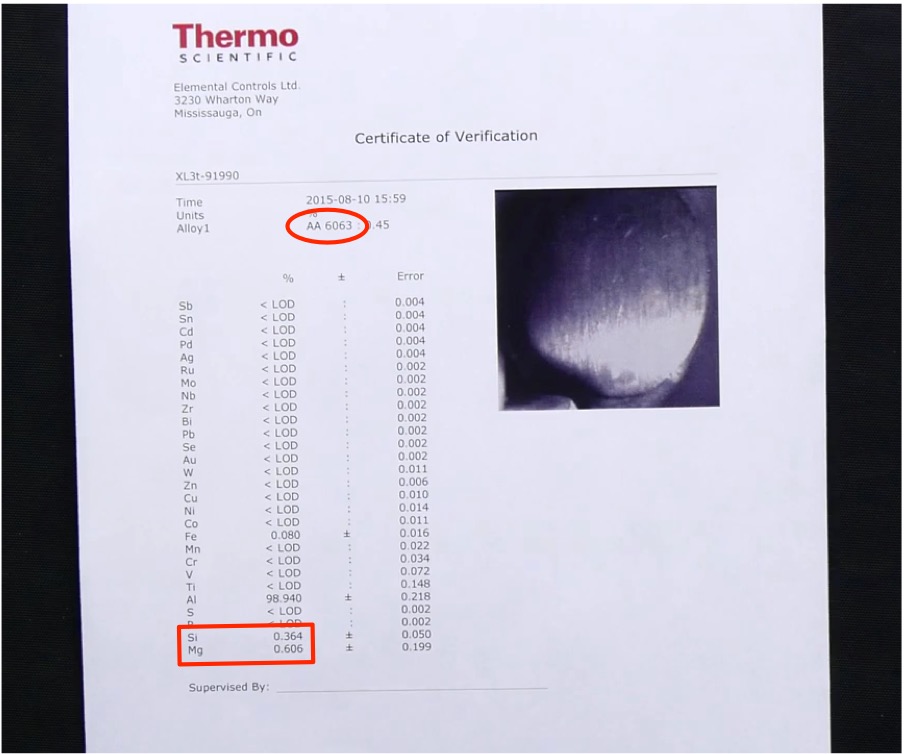

The XRF results for the current iPhone shell say it’s a 6063 aluminum. The leading “6” means the primary alloying elements are silicon and magnesium, and that’s just what the elemental breakdown shows.

Screen capture from Unbox Therapy.

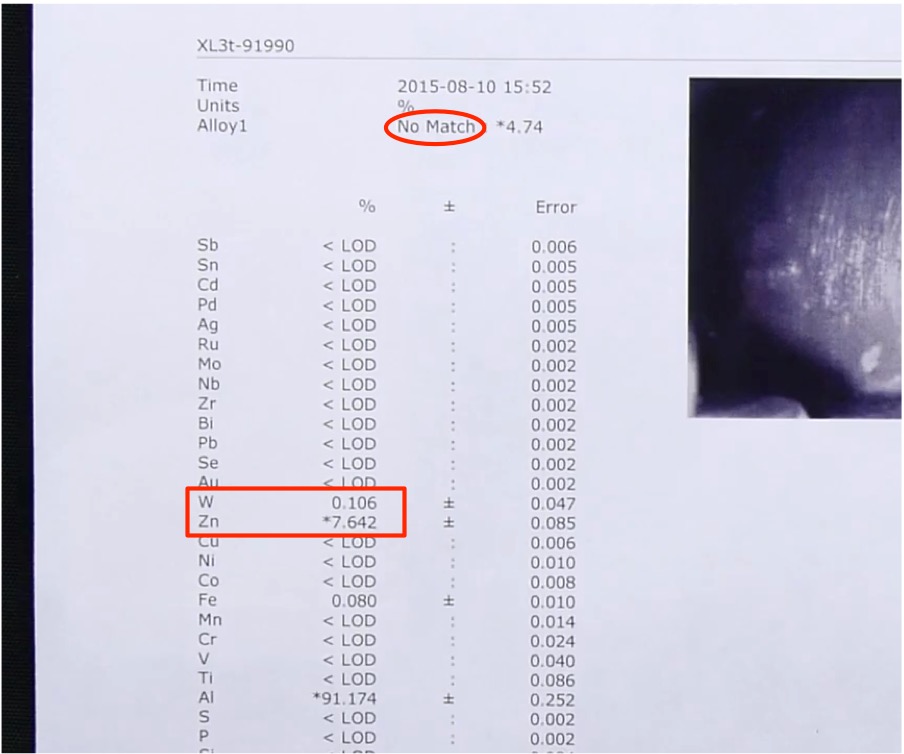

The XRF results for the new shell aren’t as clearcut. While it’s obvious that zinc is the primary alloying element, which means the alloy is in the 7xxx series, the software didn’t find a good match in its database. Lew didn’t say anything about this in the video, but you can see it in the area I’ve circled at the top of the report.

Screen capture from Unbox Therapy.

I did a little looking around in my aluminum references, and I didn’t find a match, either. What’s weird is the tungsten (W) at 0.106%. I don’t have any aluminum specifications that call for tungsten, and in the 7xxx specs I’ve seen, “other” elements are limited to 0.05%.

In the video, Lew finesses this unknown by calling the new material “7000 series,” which is certainly true, but it’s not the whole truth. To me, the fact that the aluminum in the new shell doesn’t meet a standard specification is one of the most interesting findings. It suggests that Apple has developed its own proprietary aluminum alloy.

It wouldn’t be the first time Apple’s done this. The Apple Watch Sport uses a proprietary 7xxx alloy, which is mentioned on both the “Craftsmanship” page and in Jony Ive’s “Aluminium” video, which is where I got that splashy image.

The natural question is “Is this new iPhone aluminum alloy the same as the Apple Watch Sport alloy, or was it developed specifically for the iPhone?” Since I haven’t seen the chemistry of the Sport alloy, I have no idea what the answer is. Maybe that’ll be in an upcoming Unbox video.

What I dislike most about the video is the impression it gives that an alloy’s elemental content determines its strength. This is terribly misleading. Chemistry is important, of course, and 7xxx alloys are generally stronger than 6xxx alloys, but you can’t know how strong these alloys are without knowing their heat treatments.

Heat treatment is the sequence of heating and cooling steps applied to an alloy after solidification. Both the 6xxx and 7xxx series of alloys are specifically designed to be strengthened through heat treatment, and the degree of strengthening can be significant. For example, a fully annealed 6063 (6063-O) has a yield strength of about 7,000 psi, while a solution heat treated and artificially aged 6063 (6063-T6) has a yield strength of about 31,000 psi.3 These are alloys with exactly the same elemental composition. It’s like the difference between a blob of dough and a fully cooked loaf of bread.

By comparison, if we look at the typical properties of a 7075 alloy (commonly used in aircraft parts), the fully annealed (7075-O) yield strength is 15,000 psi and the solution heat treated and aged (7075-T6) yield strength is 73,000 psi. Again, the heat treatment tells the tale.

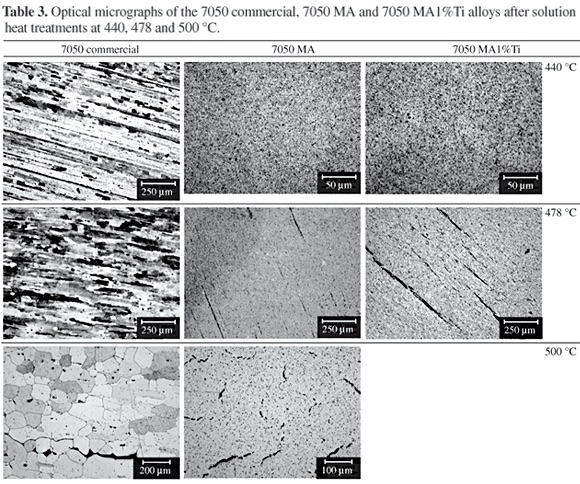

Determining the heat treatment used in a particular sample of metal isn’t as easy as determining its chemistry, and we’re starting to move away from my comfort zone. But I’d expect any metallurgist trying to make such a determination to do at least two things:

- Perform hardness tests on the metal. Because the shell is so thin, the Knoop microhardness test would be the most likely choice. Different heat treatments tend to create their own characteristic hardness levels.

- Polish and etch the metal for metallography, which is the examination of the metal’s grain structure. Different heat treatments tend to create their own characteristic grain structures.

Image from SciELO.

Perhaps when the iPhone 6S comes out, we’ll get more definitive information on the type of aluminum in its shell.

I suppose I can’t blame Lew for not putting more technical depth into his videos. He knows his audience, and he’d probably lose a lot of it if he made his videos too detailed. I don’t worry about that because my appeal is more selective.

-

For the sake of brevity, from now on I’m just going to pretend that the purported new shell really is the shell for the iPhone 6S. I know there’s reason to be skeptical, but it’s tiresome to keep throwing in the words “purported” and “alleged.” ↩

-

Not all the elements. Every spectral technique has its advantages and disadvantages, but none of them are good at detecting the lighter elements. You’ll never see an analysis that gives you the hydrogen content. ↩

-

No, I’m not going to try to explain all this heat treating terminology. Go ask your favorite metallurgist. ↩